Table Blast Machines

EFFICIENT CLEANING

Bronco TAble Blast Machines

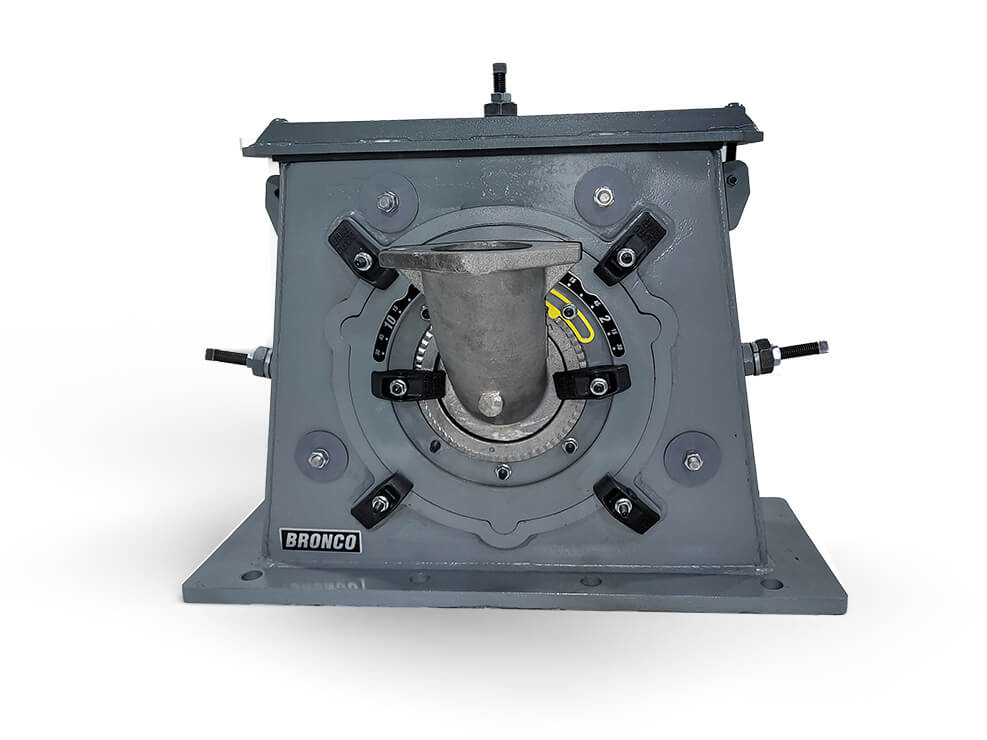

Bronco Table Blast Machines efficiently clean and continuously process a variety of part shapes and configurations, including castings, fabrications, forgings, and weldments.

Available in swing table or fixed table configurations, Bronco Table Blast Machines feature heavy-duty construction engineered to withstand the most rigorous manufacturing environments. All Bronco Table Blast Machines are fully integrated with abrasive reclaim, air wash separation, and armor plate lining systems. A variety of table sizes, clearance, and capacity options deliver the reliable, high performance that comes with the Bronco name.

BUILT TOUGH ENOUGH TO EARN THE BRONCO NAME

TAble Blast Machine

BRONCO

Table Blast Machine

OPTIMIZED CLEANING

Bronco Table blast machine standard specs

OPERATIONAL EXCELLENCE

Bronco Products and Services

Maximize Productivity

Bronco Table Blast Machines are engineered to minimize load/unload time and optimize part flow in the cleaning process.

Customize Configurations

From table sizes to clearances and capacities, Bronco engineers customize Table Blasters to solve unique cleaning challenges.

Proven Power

Multiple motor horsepower options, heavy-duty 1/2″ manganese housing, and long life cast liners provide reliable power.

Onsite Start-up Training and Support

Take advantage of expert onsite training, videos, and additional resources for safe, user-friendly blast cleaning operations.

Bronco-Certified

Preventative Maintenance

Prolong Bronco equipment life, fine-tune efficient operations, and reduce costs with regularly scheduled maintenance.

LEARN MORE

Purchasing

Options

Leasing, rental, and financing options for Bronco blast cleaning machines are available.

LEARN MORE

Request a Quote

"*" indicates required fields

Get in touch

Jayson Stemo

General Manager