Tumble Blast Machines

BUILT TO BLAST

Bronco’s Signature Line

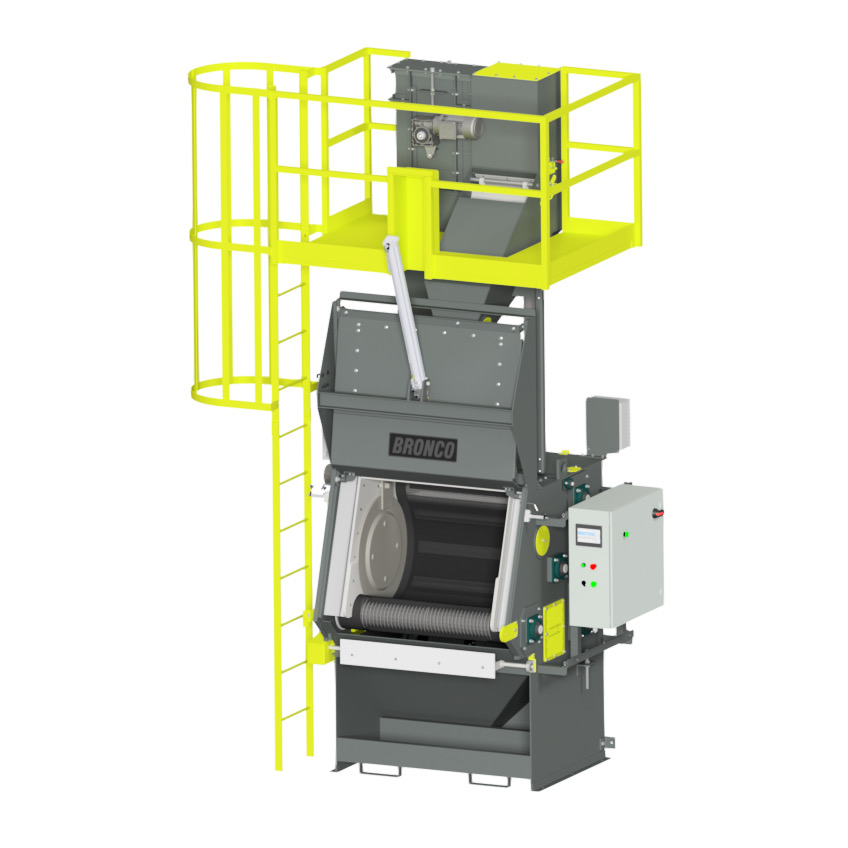

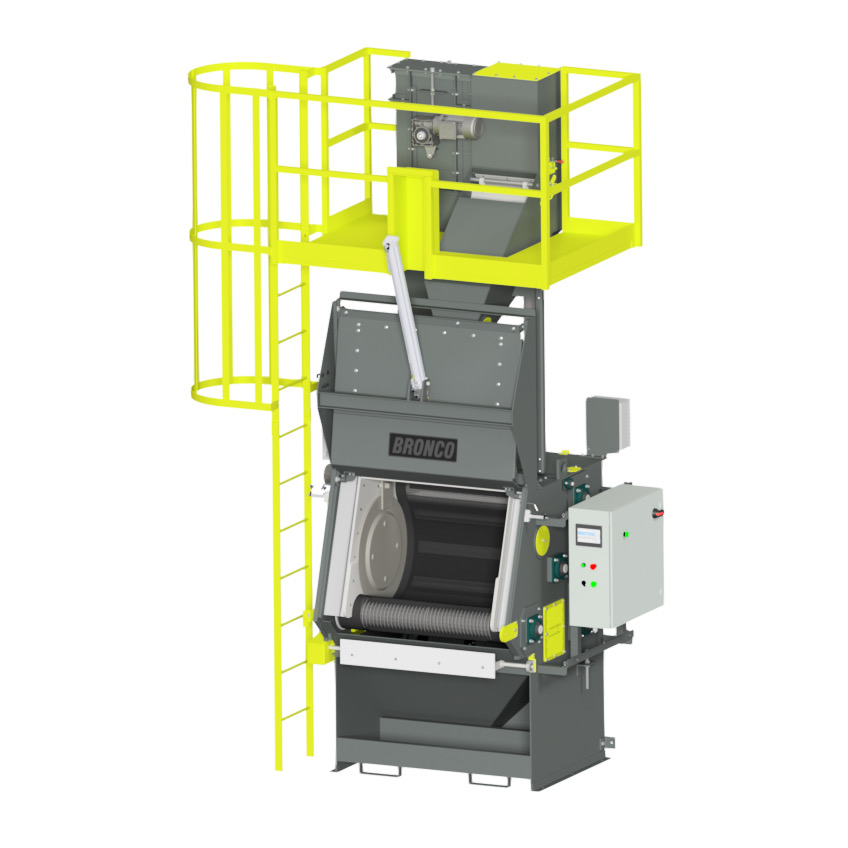

Bronco Tumble Blast Machines deliver heavy-duty, cost-effective, robust performance for batch deburring, descaling, and deflashing metal castings, forgings, aluminum die castings, and automotive parts.

Available in 3 blast capacities and built to withstand the most rigorous environment, Bronco Tumble Blasters are fully integrated, high-performance blast solutions assembled in the US and engineered with the relentless quality and operational excellence you expect from the Bronco name.

SIZED TO OPTIMIZE

3 Signature

Bronco Tumble Blast Machine Sizes

Tumble Blast

3.5 Cubic Foot

Tumble Blast

6.5 Cubic Foot

Tumble Blast

14 Cubic Foot

ENGINEERED EFFICIENCY

Bronco Tumble Blast Machine

Standard Specs

OPERATIONAL EXCELLENCE

BRONCO PRODUCTS AND SERVICES

Intuitive and Automated

Machine Controls

Innovative touchscreen controls optimize productivity and ensure easy custom programming and trouble-free operations.

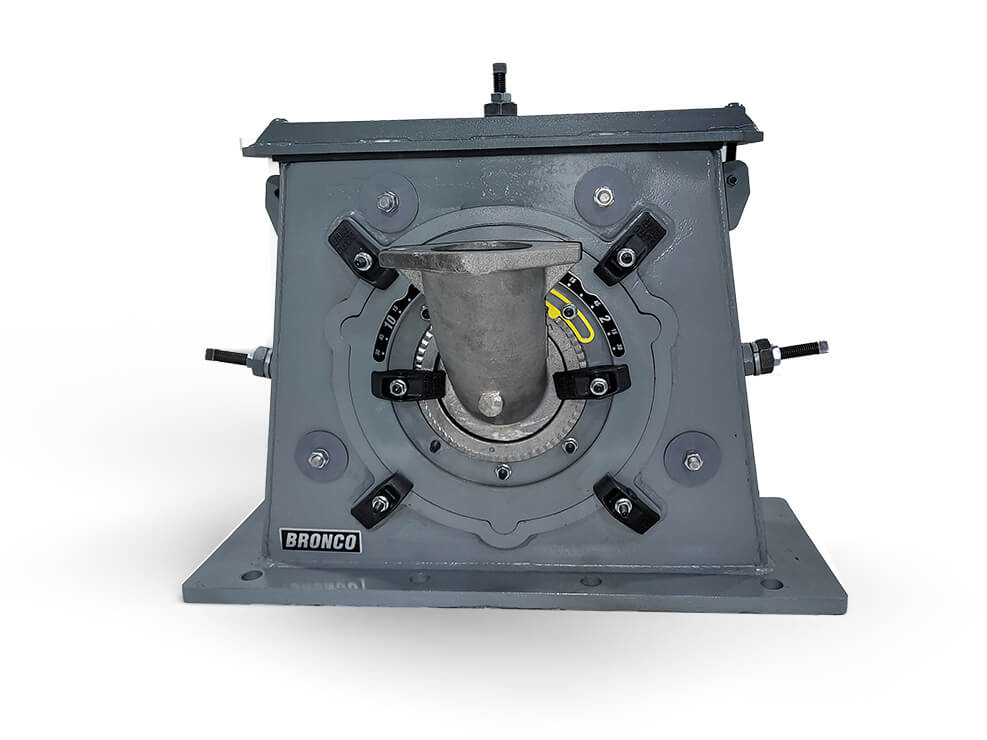

Standard Heavy-Duty

Mill Belt

A thicker belt comes standard in all Bronco Tumble Blast machines to reliably handle the smallest parts and avoid jamming.

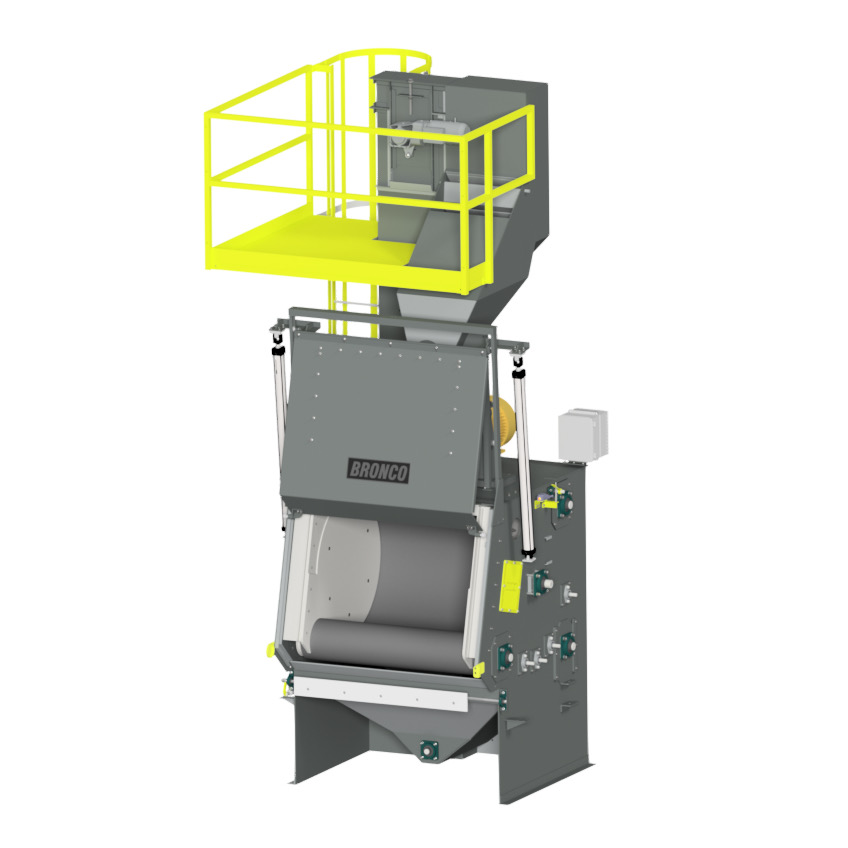

Customizable

Applications

Bronco engineers can tailor a fully integrated tumble blaster to your specific parts, production needs, and plant layout.

Onsite Start-up

Training and Support

Take advantage of expert onsite training, videos, and additional resources for safe, user-friendly blast cleaning operations.

Bronco-Certified

Preventative Maintenance

Prolong Bronco equipment life, fine-tune efficient operations, and reduce costs with regularly scheduled maintenance.

LEARN MORE

Purchasing

Options

Leasing, rental, and financing options for Bronco blast cleaning machines are available.

LEARN MORE

Request a Quote

"*" indicates required fields

Get in touch

Jayson Stemo

General Manager